News Room

Utilizing Alkali Elements in Kraft Pulping

April 30, 2019

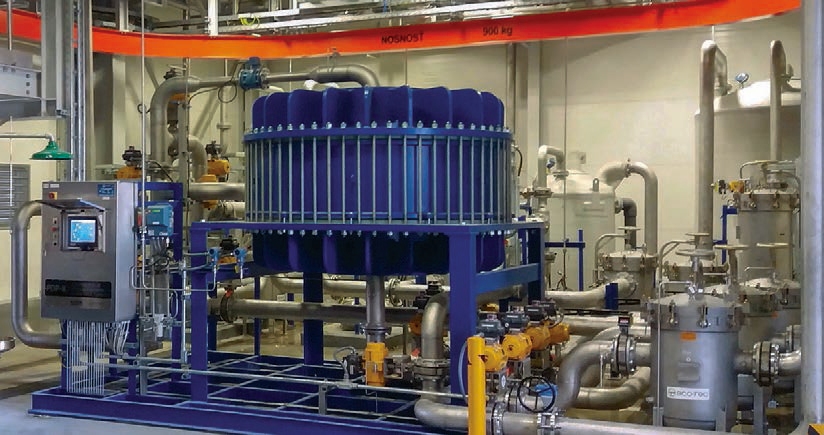

Mondi SCP has implemented a novel PDP-K™ system to optimize the potassium chemistry in their bleached kraft pulp mill in Ružomberok, Slovakia. The first-of-its-kind facility was adapted by NORAM using a proprietary Eco-Tec Ltd. (Canada) ion-exchange platform.

Potassium introduced in the wood supply normally builds up due to improved chemical recovery and reuse practices in modern mills. Established purging technologies were ineffective at the high potassium concentrations experienced at Ružomberok, and furthermore wasted the potassium’s potential value as an alkali. The new plant extracts potassium from the kraft recovery cycle, where potassium contributes to plugging and corrosive conditions in the recovery boiler, and transfers the potassium to the kraft bleach plant in the form of potassium hydroxide, saving an equivalent amount of sodium hydroxide. This is the tenth installation of PDP for process ion-exchange in the pulp and paper industry.

© 2025 NORAM Engineering and Constructors Ltd.